Sage Titanium PDXCX

Details

The ’Cross Racer’s ‘Cross Bike

Bring on the tempests. Bring on the muck. Bring on the drops, the roots and the ruts. The PDXCX begs for it all. Born in the heinous mud of the Pacific Northwest and bred on the technical courses of the Cross Crusade, it’s a cyclocross race machine. This is a ‘cross racer’s ‘cross bike.

Drawing inspiration from classic Belgian cyclocross bikes, the PDXCX adds modern touches of refinement to those traditional frame designs. We purpose built the fourth iteration of this frame to power through the mire and greasy corners with precise stability. Bottom Bracket height and short chainstays are optimized to improve handling and snap while preserving the nimble characteristics that make the geometry a perfect race setup. The ovalized top tube and oversized head tube stiffen the front end for the confidence and precision to nail the perfect line. The bike is designed nail the apexes and slam through ruts all the way to the finish line.

As modern hydraulic brakes have become more reliable, internally routed brake lines are less of a hassle than they used to be due to the reliability of the equipment. All Sage bikes now use internal routing for our brake lines but for those who still want the ease of maintenance with an externally routed brake, we can accomodate that.

All Sage bikes now come with our custom designed 3D printed titanium dropouts that are T-Type compatible. Using these 3D printed components allows us higher quality control for the brake mounts, alignment, and they are considerably lighter than a standard dropout setup

The bike is bombproof and built to withstand the most diabolical racing and riding conditions. The titanium construction offers a much higher strength-to-weight ratio compared with other metal frames, and the 3/2.5-titanium alloy tubing has exceptional corrosion resistance. Blast every nook and crevice with the power washers—this bike will thrive and shine, not wither and rust. In the event of a scuff, fear not! The raw industrial finish is one of the most durable and repairable of titanium finishes. Any scratches can be buffed out with a Scotch-Brite pad, restoring that lusty, like-new sheen to this burly beauty.

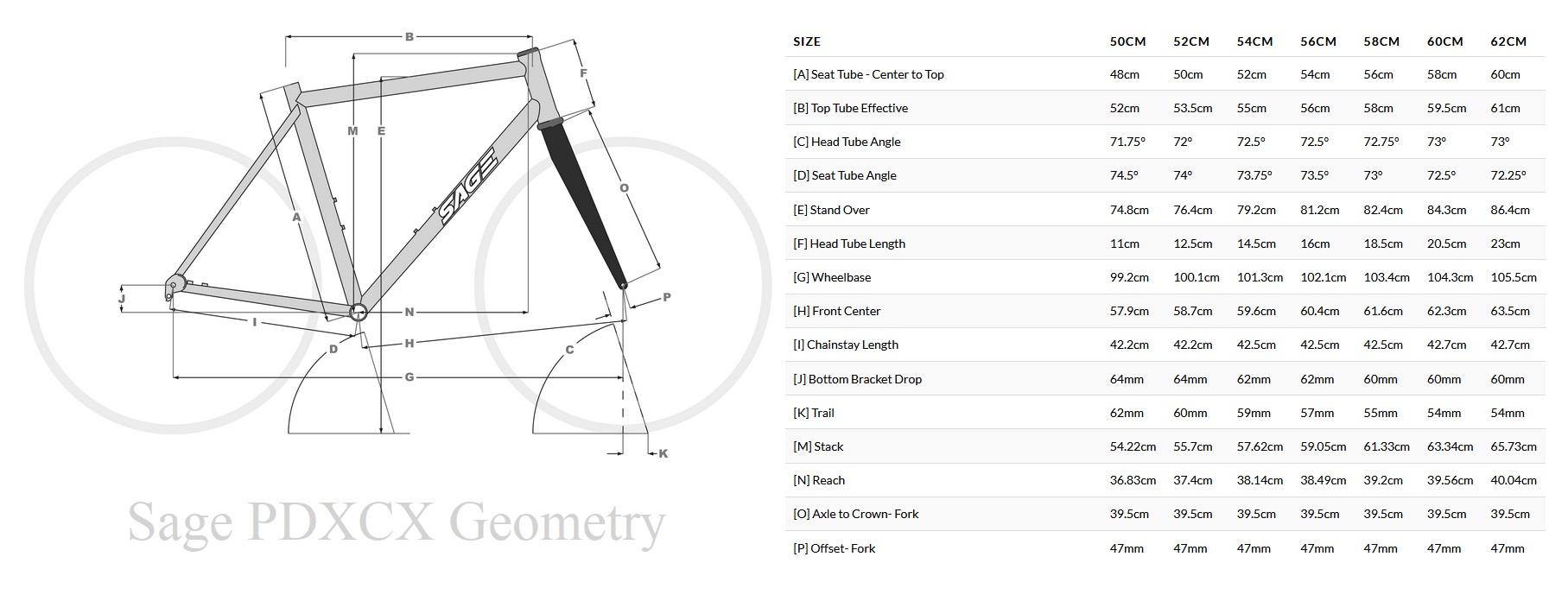

Available in standard geometries or as a custom frame. For more information please contact Sage at SageTitanium.Com or the Sage experts of Lakeside Bicycles by phone (W-F 10-7, Sat 10-6, or Sun 12-5) at 503-699-8665 or by email at Info@Lakeside-Bikes.com.

At Sage, 3/2.5 titanium is the magic material. The smooth riding alloy blends stiffness, durability and weight for the ultimate frame tubing. Titanium has a superior strength-to-weight ratio compared with steel and aluminum, and the fatigue tolerance far surpasses the other materials. Don’t fret long rain rides or brackish water crossings—3/2.5 titanium resists rust and corrosion better than any other metal tubing.

Clearance for up 40mm tires

Custom 3D printed titanium dropouts and chainstay yoke options are now available on all Sage bicycles. Our dropouts are SRAM Transmission/ T-Type compatible so your bike is future proofed whether you are riding road, gravel, or MTB. The chainstay yokes are designed for max tire clearance and minimal chain stay lengths to provide better acceleration and snap out of the corners. 3D printed parts are lighter and stronger than standard welded parts due to the unique nature of the printing and heat treating process. Our parts are specifically designed to meet the rigors and demands for performance oriented bikes.

Custom 3D printed titanium dropouts and chainstay yoke options are now available on all Sage bicycles. Our dropouts are SRAM Transmission/ T-Type compatible so your bike is future proofed whether you are riding road, gravel, or MTB. The chainstay yokes are designed for max tire clearance and minimal chain stay lengths to provide better acceleration and snap out of the corners. 3D printed parts are lighter and stronger than standard welded parts due to the unique nature of the printing and heat treating process. Our parts are specifically designed to meet the rigors and demands for performance oriented bikes.

Ovalized and shaped tubing for race ready performance

Classic and classy yet updated for the modern era, the T47 bottom bracket reigns supreme over press-fit alternatives. The strong interface between bottom bracket cups and the frame eliminates creaks and maintains alignment that won’t slip or wobble over time. Additionally, installation, removal and service of the design are simply superior. No punching or pressing required. Just thread it, grease it, shred it. Repeat.

Borrowed from the mountain bike realm, the oversized 44-millimeter head tube affords phenomenal front-end stiffness and precision on the road. Press-in headset cups provide a secure interface between frame and cockpit, and the large diameter opening accepts a wide range of steerer tubes, from 1?-inch straight to 1?–1½-inch tapered and every combination between.

Handling is designed for wet/ tight/ technical courses

Optional Stealth fender mounts for increased weather protection during off season training rides

Internally routed brake lines, Di2 wires, and mechanical drivetrains are now standard options on Sage frames. External brake and mechanical shift lines options are still available if requested. Please let us know in advance.

All Sage frames come with our Blasted Finish option as a base choice. You can choose either a raw titanium finish with blasted graphics, or a blasted finish with raw graphics. The unique look of titanium metal lends itself to the finish choices listed here. No worries about decals getting scuffed or the graphics fading over time. These finish choices will be for the lifetime of the bike. We also offer Cerakote, Anodize, and Wet Paint options for those clients that want to add some color and unique finishes and touches to their bikes.

Custom Sage Titanium Frames